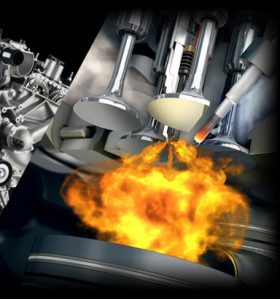

Petrol engine - Diesel engine

Petrol engine - Diesel engine - Theoretical basics. Fundamentals and functional principles of combustion engines. Didactically prepared teaching devices for a simple understanding of the technology in vehicles.

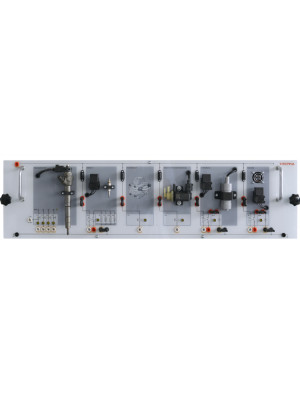

This module panel is part of T-Varia Engine Management. This unit can be used in conjunction with the "Engine Sensors", "Engine Control Unit" and "Eng..

This module panel is part of the T-Varia Starter Set Engine Management. This unit can be used in conjunction with the "Engine Sensors", "Engine Contro..

This module panel is part of T-Varia Engine Management. This unit can be used in conjunction with the "Engine Sensors", "Engine Control Unit" and "Eng..

This module panel is the central part of the T-Varia Starter Set Engine Management. This unit can be used in conjunction with the "Engine Sensors", "E..

This module panel is part of the T-Varia Starter Set Engine Management. This unit can be used in conjunction with the "Engine Sensors", "Engine Contro..

This module panel is part of the T-Varia Starter Set Engine Management. This unit can be used in conjunction with the "Engine Control Unit", "Engine D..