Search - hybrid

Products meeting the search criteria

This is a cut-away model of automobile chassis called "Hybrid System Car". The model is sectioned to show its component parts and operation mechanism...

This is a cut-away model of automobile chassis called "Hybrid System Car" base on a Toyota Prius 4th generation. The model is sectioned to show its co..

Volkswagen Golf GTE converted into a training vehicle. Didactically valuable selection of learning situations and diagnostic options with 90 faults, 3..

This is a cutaway model of an automobile drive called "Hybrid System Car". The model is sectioned to show its components, parts and the operation..

This is a cutaway model of an automobile drive called "Hybrid System Car" based on a Toyota Prius 4. The model is sectioned to show its component..

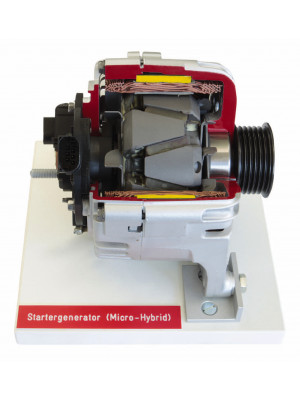

Cutaway Model Starter alternator (micro-hybrid) The STARS system is able to switch the engine off at a red light or in a traffic jam and to restart th..